At Garmo Instruments our purpose is to conceive innovative ideas. Our target is to update your application with technologically advanced and easy to use systems and sensors. The key is to make automated welding even easier.

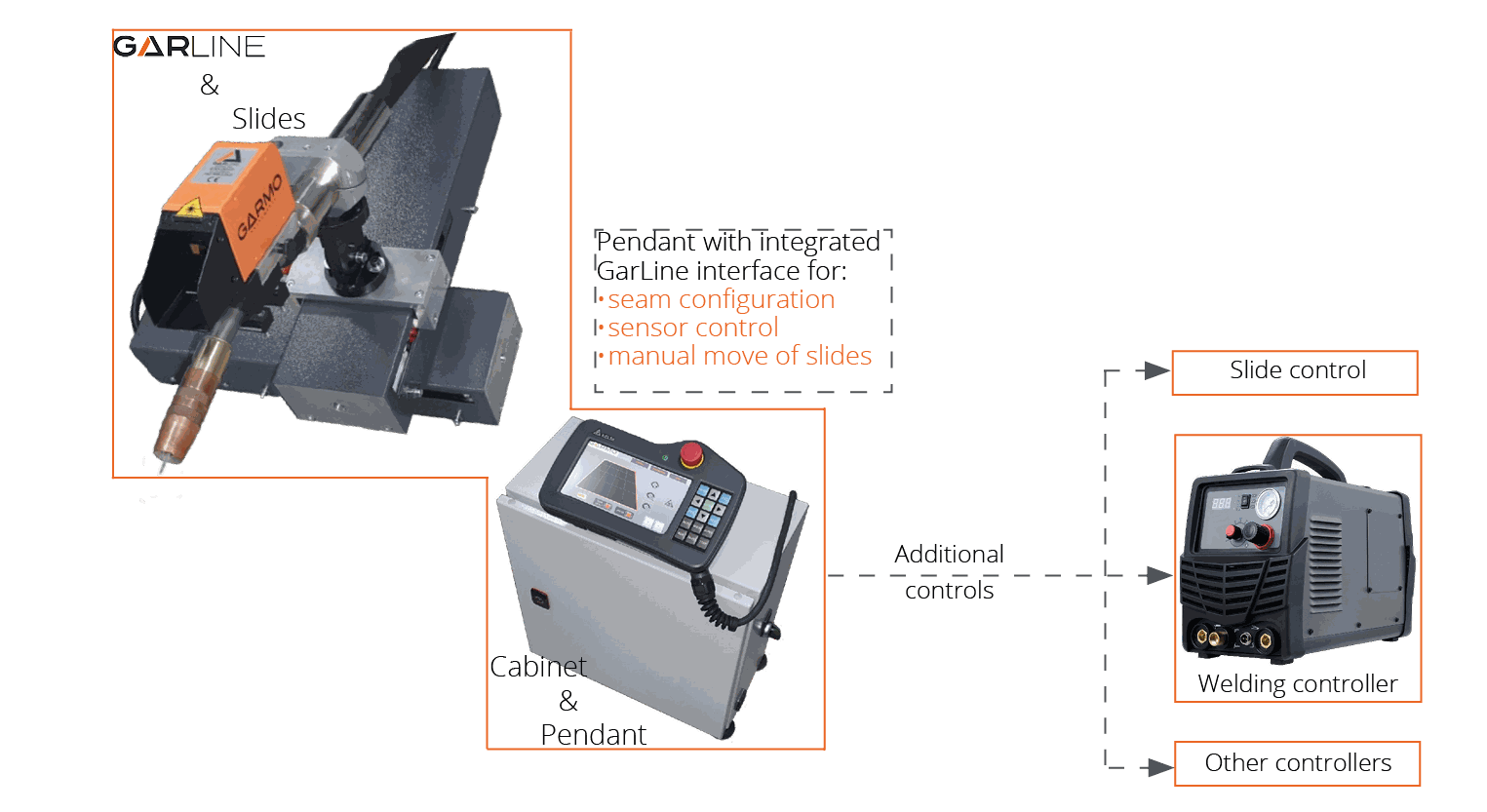

Introducing SharpTrack — An all-in-one easy welding kit with flexible customization. Reach a complete automation of your welding application and get the full control of the whole system in just one kit!

Features

Customizable

Configure and personalize your SharpTrack to your application needs and requirements. Full access to all the functions. And all using just the Pendant as a tool!

Easy setup

Simple installation, and no extensive programming required. SharpTrack already includes pre-defined and customizable programming, making welding automation even easier.

Ground-breaking functions

Enjoy the accuracy of automated welding with GarLine PLC’s ultimate functions:

-

Seam end-detection tracking

-

Pre-tag avoid configuration

Discover SharpTrack

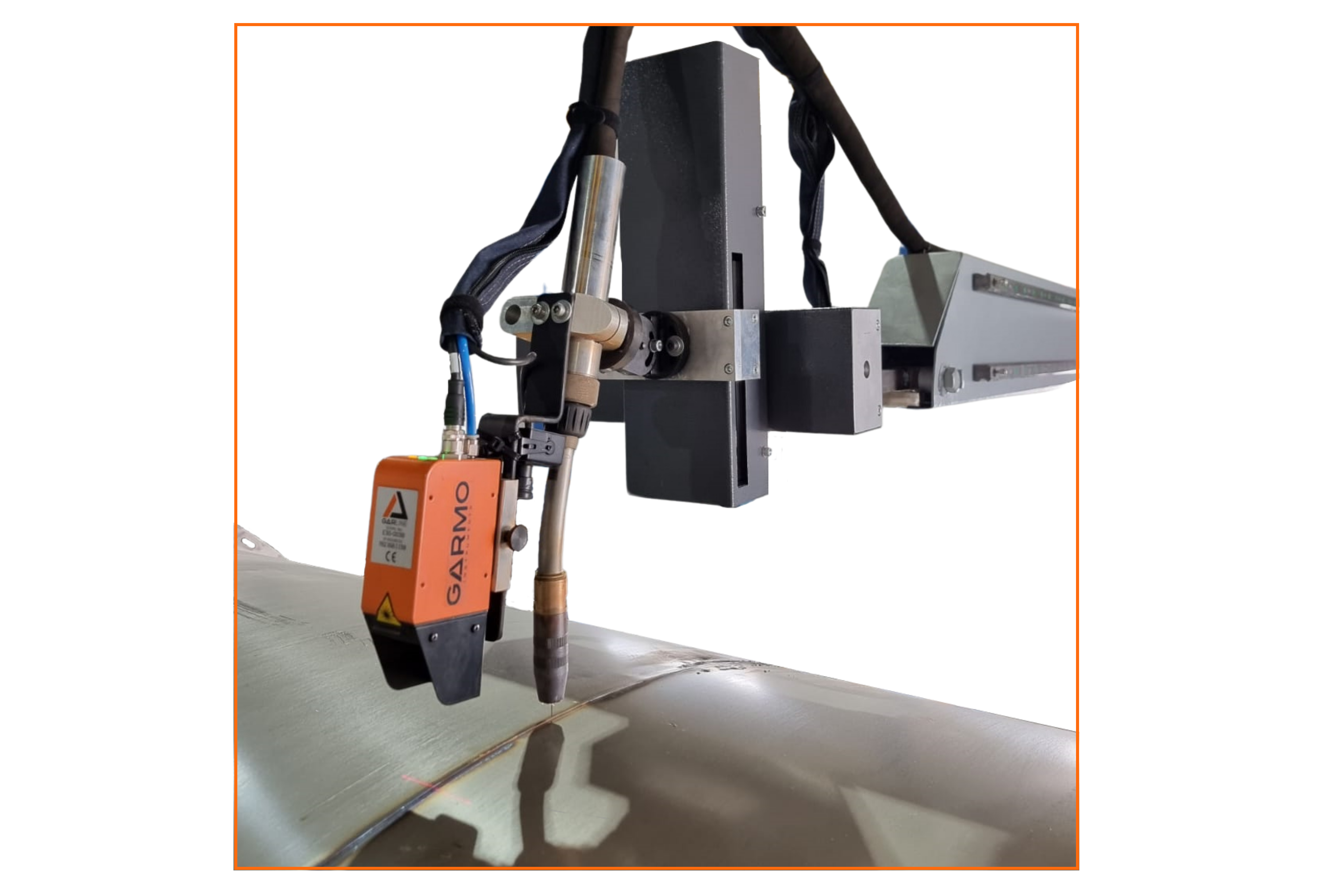

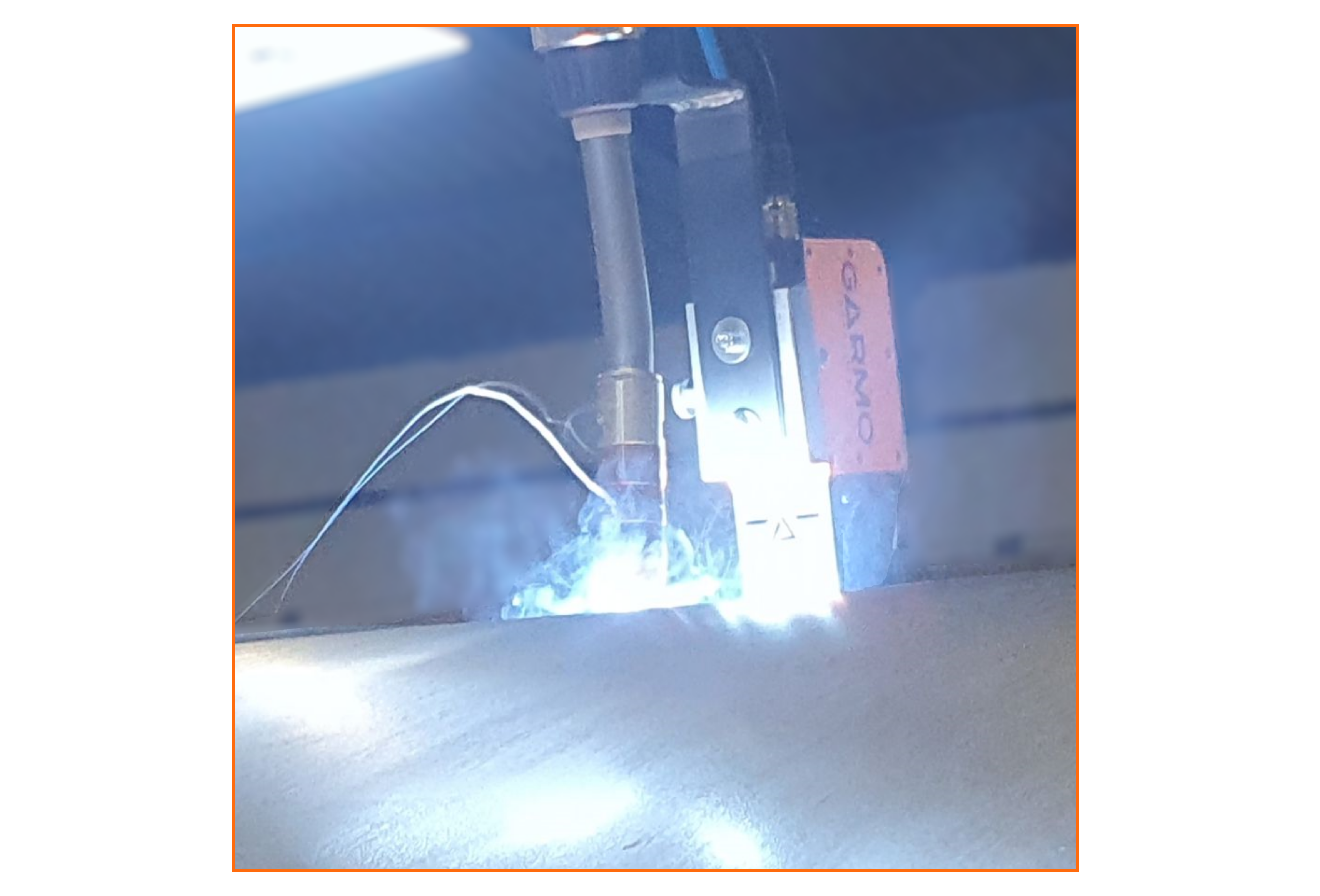

Accurate tracking and corrections

Real-time seam tracking and microcorrections of welding torch trajectory thanks to GarLine’s look-ahead function.

GarLine sensor carries out corrections at such speed that it is imperceptible to the eyesight.

This precision, in addition to providing flawless quality welds, ensures a pristine perceived value in the end product.

100 % Customizable

Design your application

Configure your entire application according to your needs, along with all its components, in a single kit. With SharpTrack you’ll be able to:

-

access the multiple and flexible PLC programming options;

-

customize SharpTrack to your requirements;

-

access all welding features.

Why to upgrade your application with SharpTrack?

Safer working conditions

Workers perform in a safer environment, avoiding the traditional health-related risks since there is no longer a need in working so close to the weld, neither to the welding system.

Top quality welds

Achieve better quality results and a significantly improved perceived value of the welds with SharpTrack. Get the most benefit out of SharpTrack in your welding process.

Optimized performance

Automatic adjustments reduce downtime and improve productivity. Achieve exceptional quality and a higher rate of finished product.

How can we help you?

Thinking about automating your welding process Want to know more about this innovative solution for automated welding?

Tell us about your application, and our technical team will assist you!

Email: info@garmo-instruments.com