At Garmo Instruments, we are passionate about welding excellence. Our purpose is to develop unique, robust, simple and technologically advanced sensors and solutions for automated welding.

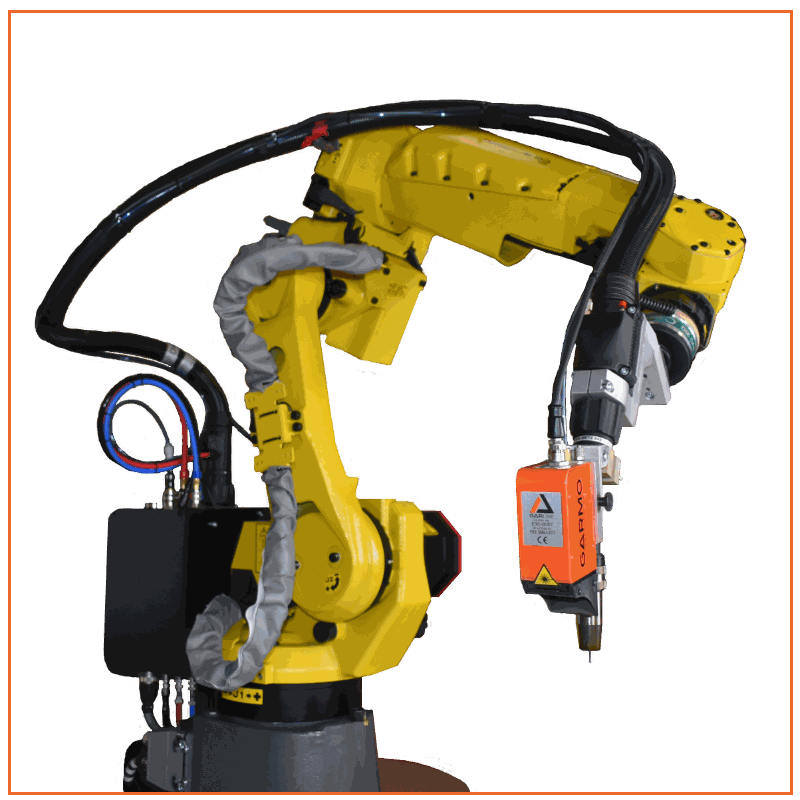

GarLine — new-generation high-performance seam tracking laser sensors for automated and robotic welding. GarLine sensor offers you a technically advanced solution, easy to integrate, implement and use.

Features

Strength & durability

GarLine is designed to last, incorporating aerospace-grade materials that ensure optimum EMI isolation, even in TIG welding processes.

With an IP67 insulation grade, it guarantees proper operation in 0°C to 70°C temperature range.

Powerful & dynamic

GarLine's electronics, with 4 parallel processes and 4Gb of RAM, computes corrections at 42 frames per second in full resolution.

It features dynamic adaptation of laser and sensor parameters between frames, an innovative feature to correct reflection problems in applications involving variable material surface conditions.

Technology & compatibility

What distinguishes GarLine sensors is the integration of a communication system adapted to new IoT technologies.

GarLine is compatible with most of TCP/IP protocols, and the web interface eliminates the need for specific software.

Discover our range of GarLine sensors

GarLine C

Universal Robots' best ally in welding

If you are already using Collaborative Robots, upgrade your cobot welding processes with the ultimate Plug & Play solution for seam tracking (with own ®UR approved URCap)

GarLine PLC

Designed to meet your needs

Take a leap to the next level and complete your PLC automated welding systems with the ultimate seam tracking solution.

GarLine R

Get the most out of robotic welding

Cutting your cycle times and improving welding quality with industrial robots is now easier, thanks to the GarLine laser sensor.

Benefits of using GarLine

Improved working conditions

Thanks to GarLine, workers are performing in a safer environment, avoiding the traditional health-related risks for, thanks to GarLine combined with automated/robotic welding, there is no longer a need in working so close to the weld.

Enriched product quality

GarLine’s optical precision and the corrections it sends to the welding torch lift companies by achieving better quality results, lower percentage of unnecessary waste and, hence, a higher rate of finished product in lower time, avoiding re-process and production losses. Gain the maximum benefit from using GarLine in your welding process.

Enhanced productivity

The simplicity of “less is more” concept is the goal for every business, including the ones belonging to welding sector. The less time is invested in production, whilst getting eminent result, the better is the productivity.

How can we help you?

Need more information about our GarLine Smart Seam Tracking Laser Sensors for Welding? Don’t hesitate to contact us.

Email: info@garmo-instruments.com

FAQ

Which seams can GarLine sensor detect?

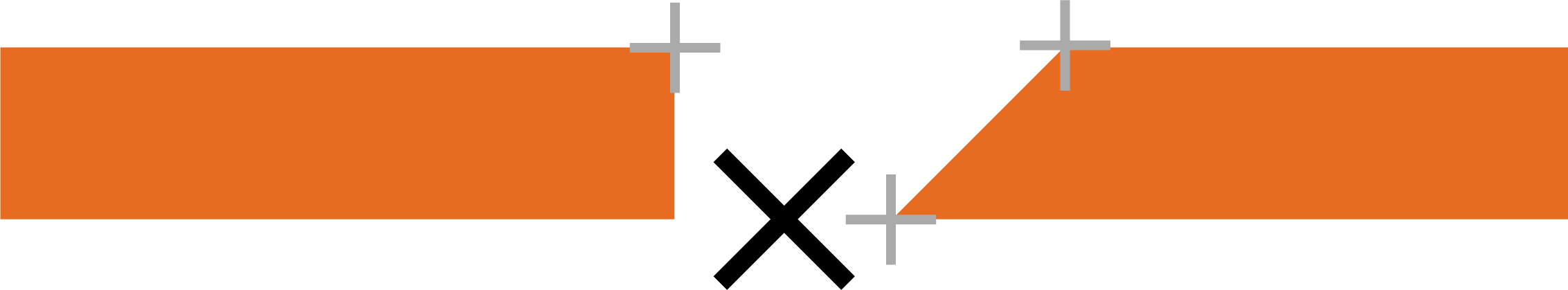

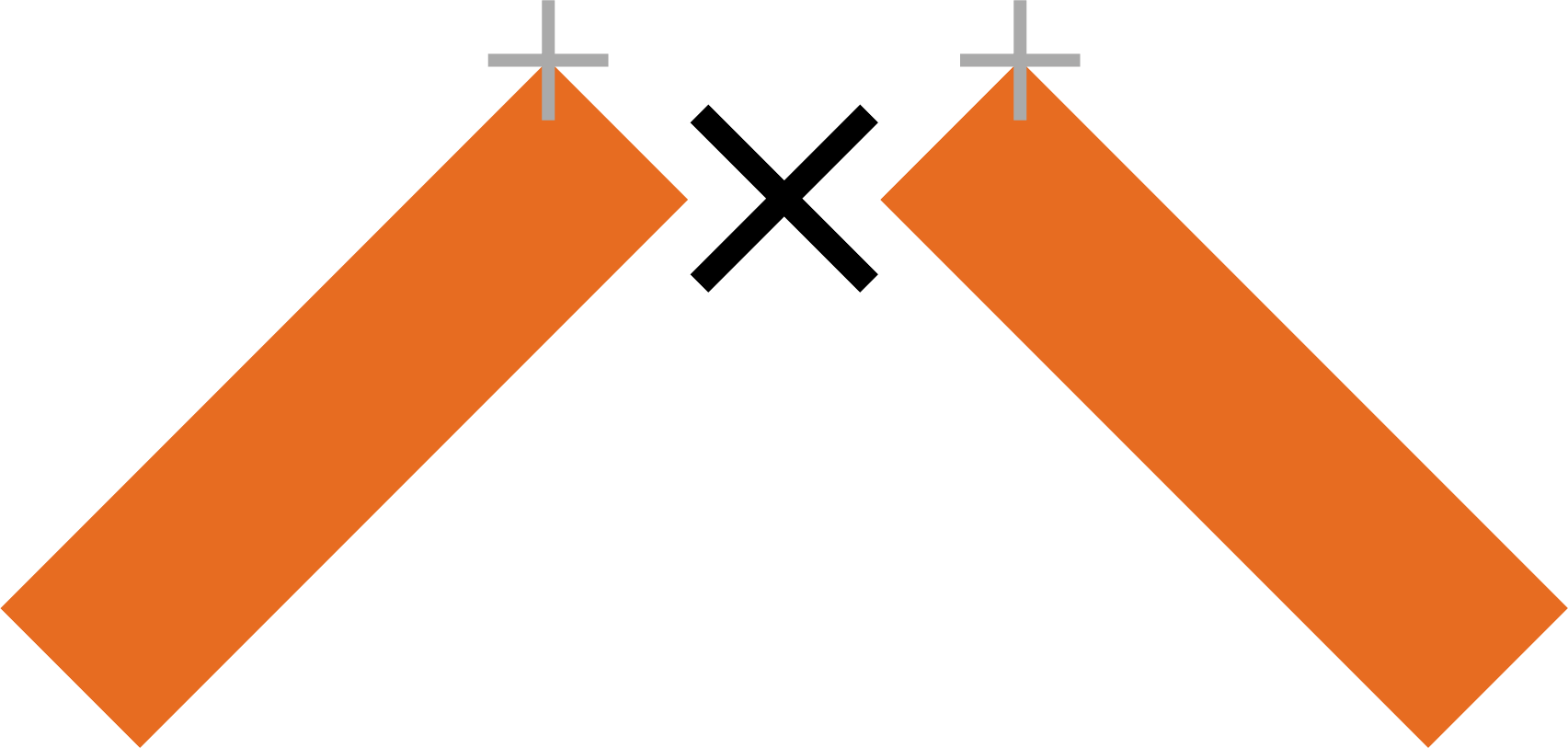

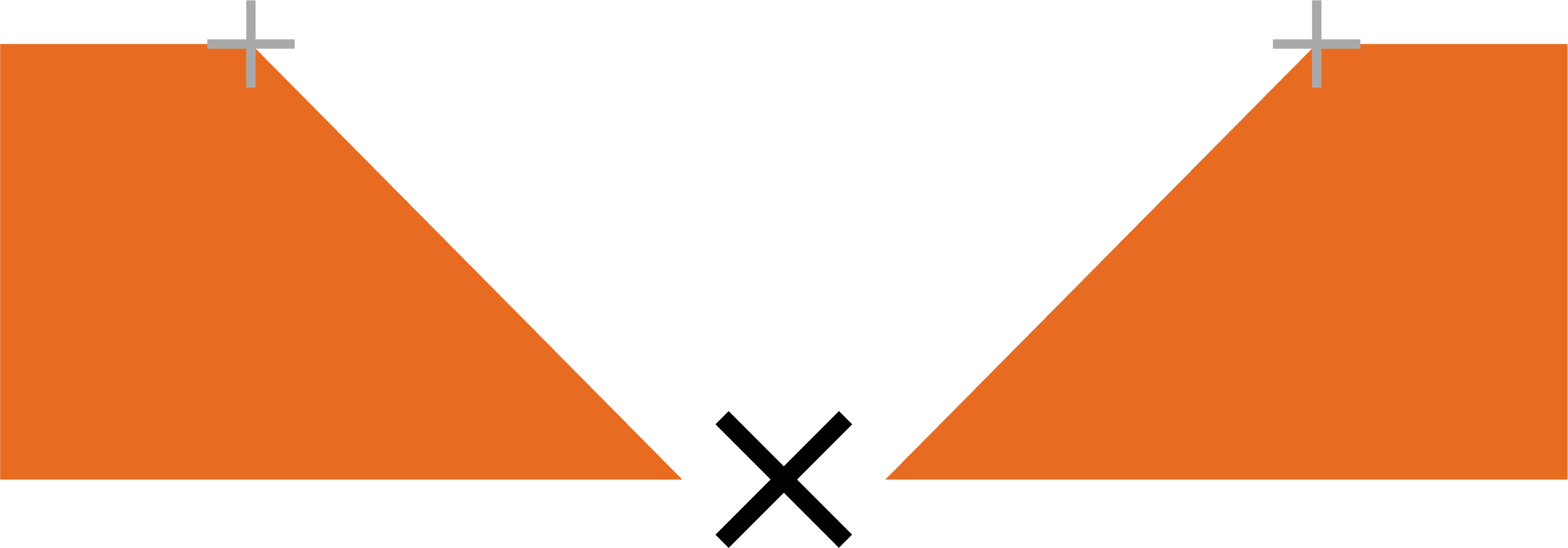

GarLine is designed to distinguish the most common welding seams. Thanks to its integrated web interface, seams can be easily detected and set up. Here are some of the seams that GarLine sensor detects:

Most common seams

Seams with bevels

Seams for pipes

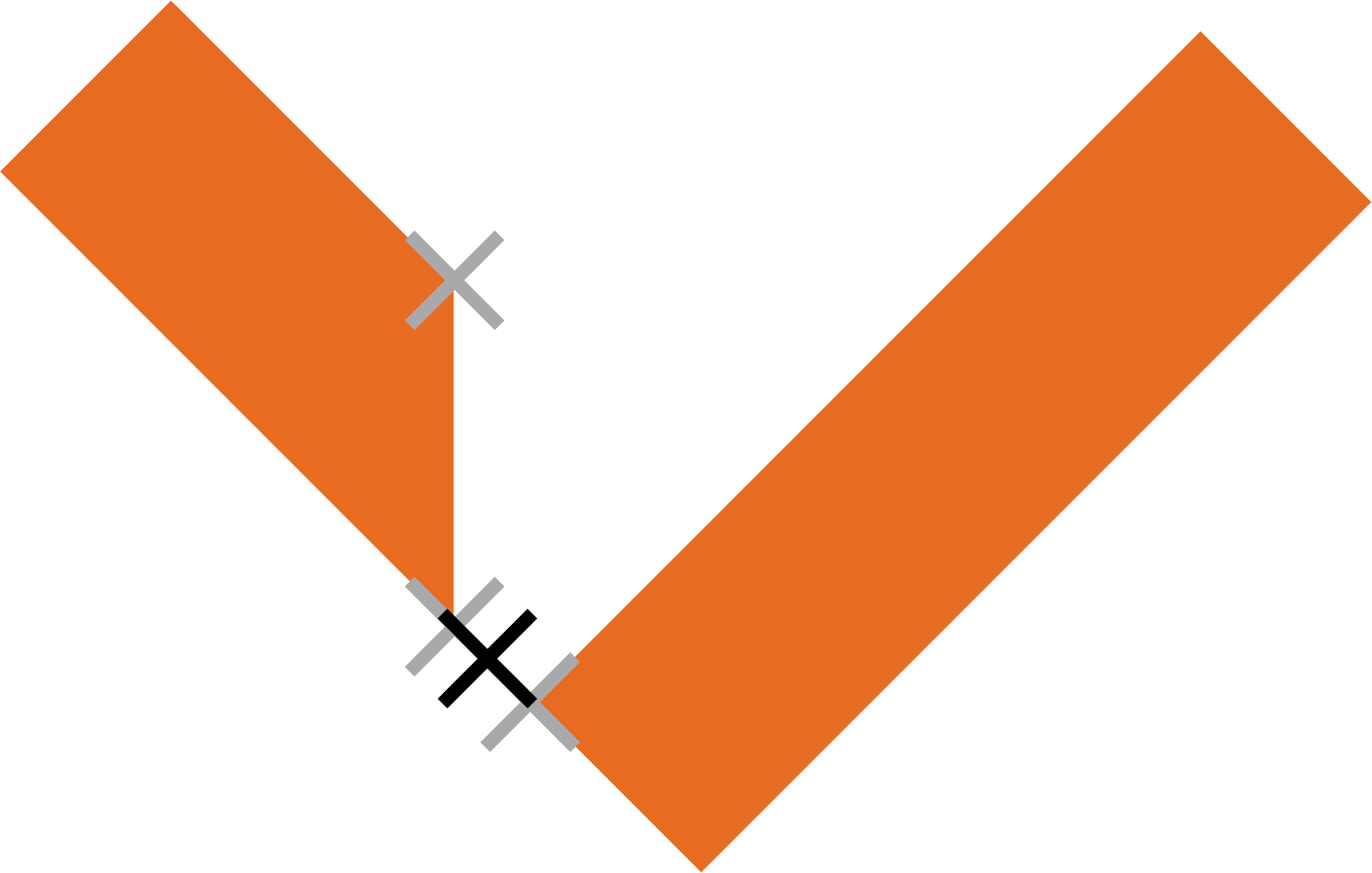

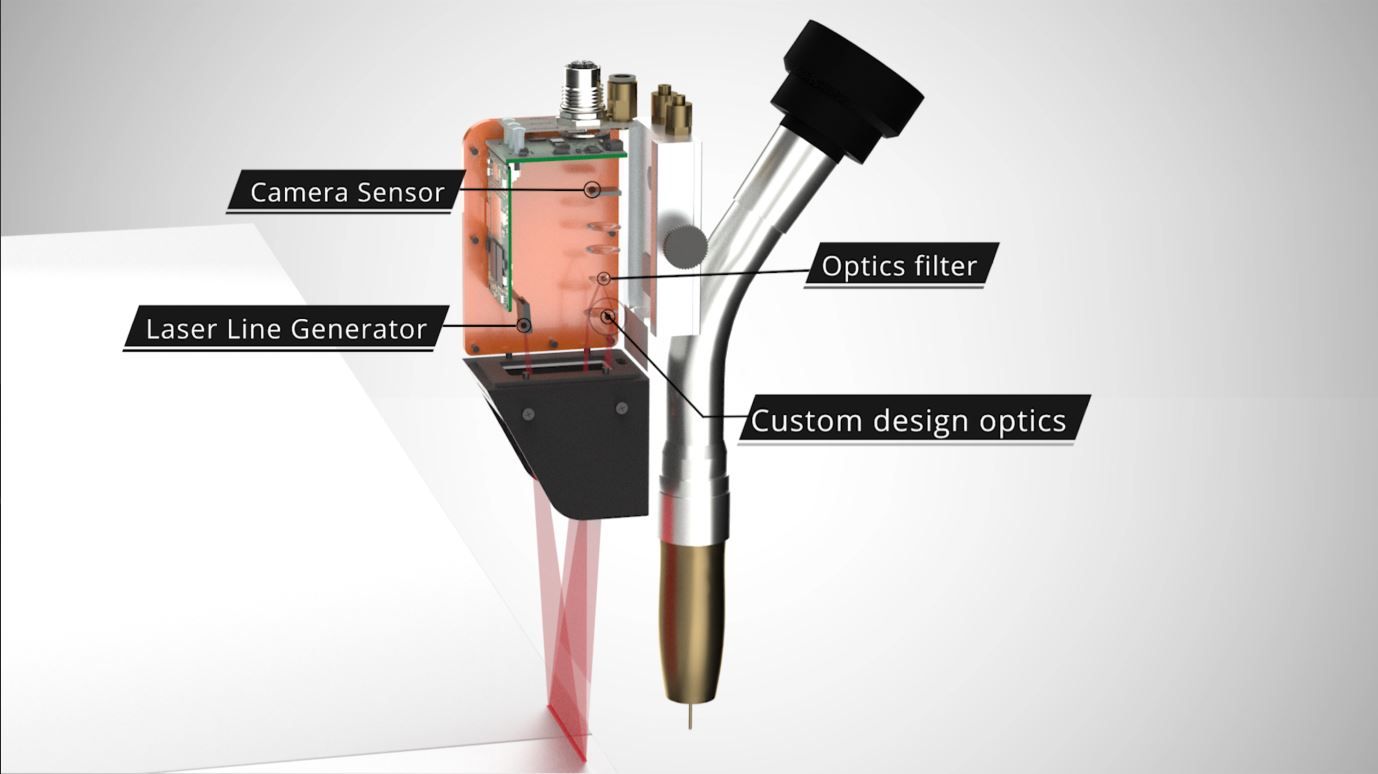

How does the laser triangulation process work?

Laser seam tracking is based on the principle of triangulation, as shown in the picture. Triangulation is a way of extracting geometrical information from measurements and has many applications. GarLine uses a structured light source (generated by a laser diode) in conjunction with an imaging device to produce a series of 2D slices through the weld joint and combine these slices to generate them into a 3D information.

The sensor projects a laser stripe across the welding joint. The stripe is then deformed by the shape of the joint. An optical filter, incorporated within the sensor, perceives only the light, which is at the same wavelength as the laser, projecting it into the 2D camera (in other words, the filter cleanses any light except for the one projected by the laser). Once the sensor perceives the seam shape, the internal electric circuit processes the image and spots the welding key points.

GarLine sensor incorporates advanced electronics that enables the adaptation of the parameters of laser power and camera gain, to adapt to the color variations of the materials. Since these electronics are incorporated within the sensor, the adaptation between frames is made at 42 images per second speed.

How can I incorporate GarLine into my system?

GarLine includes a series of welding seam libraries and examples that don't require a professional programmer for integration, basic notions of PLC programming are enough to successfully incorporate GarLine into the system. These libraries include PLC integration sections and examples of the integration into HMI.

In case of integration into cobots, Garmo Instruments offers a URcap integration to enable a fast implementation.

Which maintenance does GarLine require?

GarLine is designed to offer user a minimal sensor maintenance. Thanks to sensor's polycarbonate frontal disposable protective window, its splatter shield, the air flow through the sensor head and its easy mounting and dismounting system on the water-cooled mounting plate, GarLine sensor is protected against any possible damages that could be produced by welding process (moisture, splatter, dust, etc.). Sensor maintenance is simple - depending on the welding process, the protective polycarbonate window would be replaced more or less regularly (the window replacement process is quick and easy). For a more in-depth cleansing, the sensor can be easily removed from the mounting plate, without any need in additional tools, and the external sensor housing can be easily cleaned. Thanks to the IP67 protection, the Gorilla Glass internal protective window and sensor's waterproof coating, GarLine's cleansing and maintenance are made simple.

What kind of laser does GarLine use?

GarLine employs a 3R class laser which is equipped with advanced technology and operates at a lower frequency than other laser sensors, that use a 3B class laser. What differs a 3R laser is the security that it offers at the workplace since, unlike other sensors, GarLine’s laser isn’t harmful to eyesight, even if the sensor is handled without protective glasses.

What is PoE?

Power over Ethernet (PoE) is a technology that enables network cables to carry electrical energy.

A regular sensor normally needs two wires: a power wire and a network wire to connect sensor to the system. It’s usual to find these wires joined into a single non-standard wire with specific connectors.

Nevertheless, if the sensor can support PoE, just one standard wire is required, usually a Cat6e wire type or higher, since both power and connection data would be transferred through it.

Power over Ethernet reduces the number of wires needed to connect the sensor, and the number of non-standard wires.