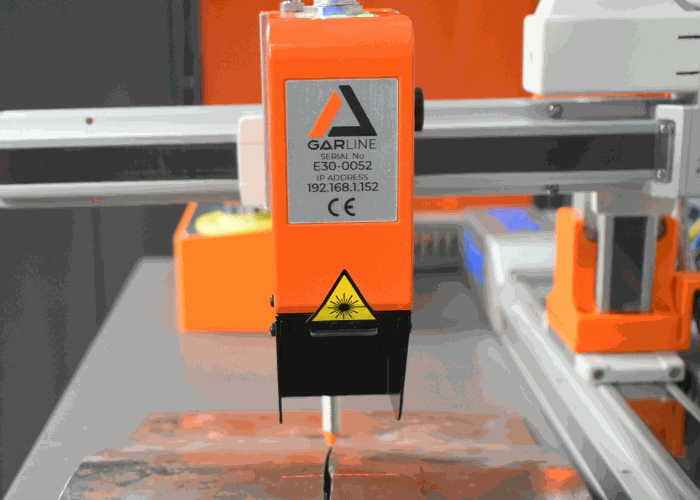

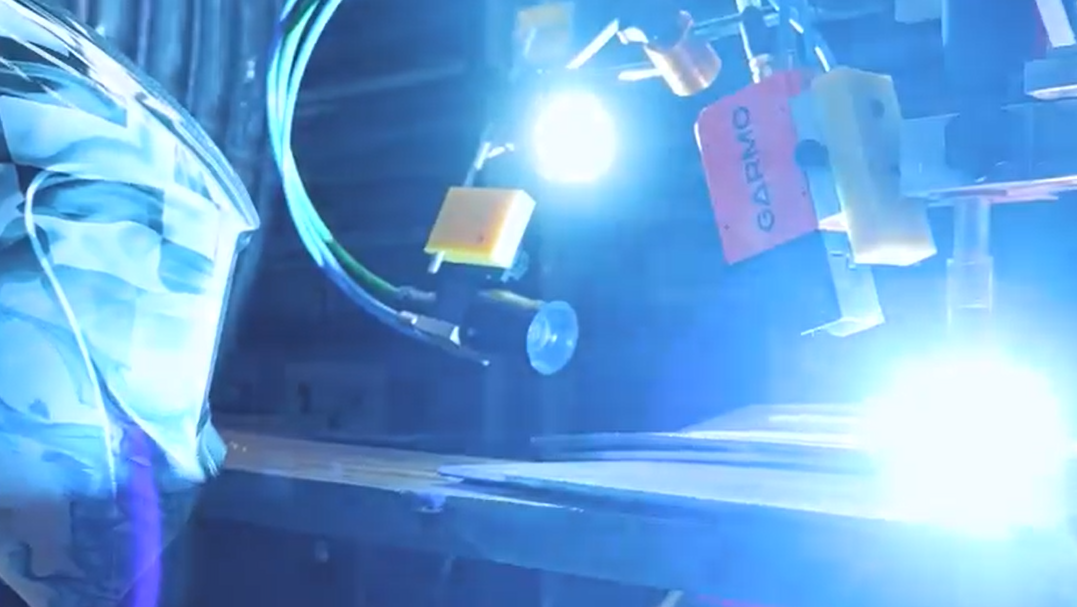

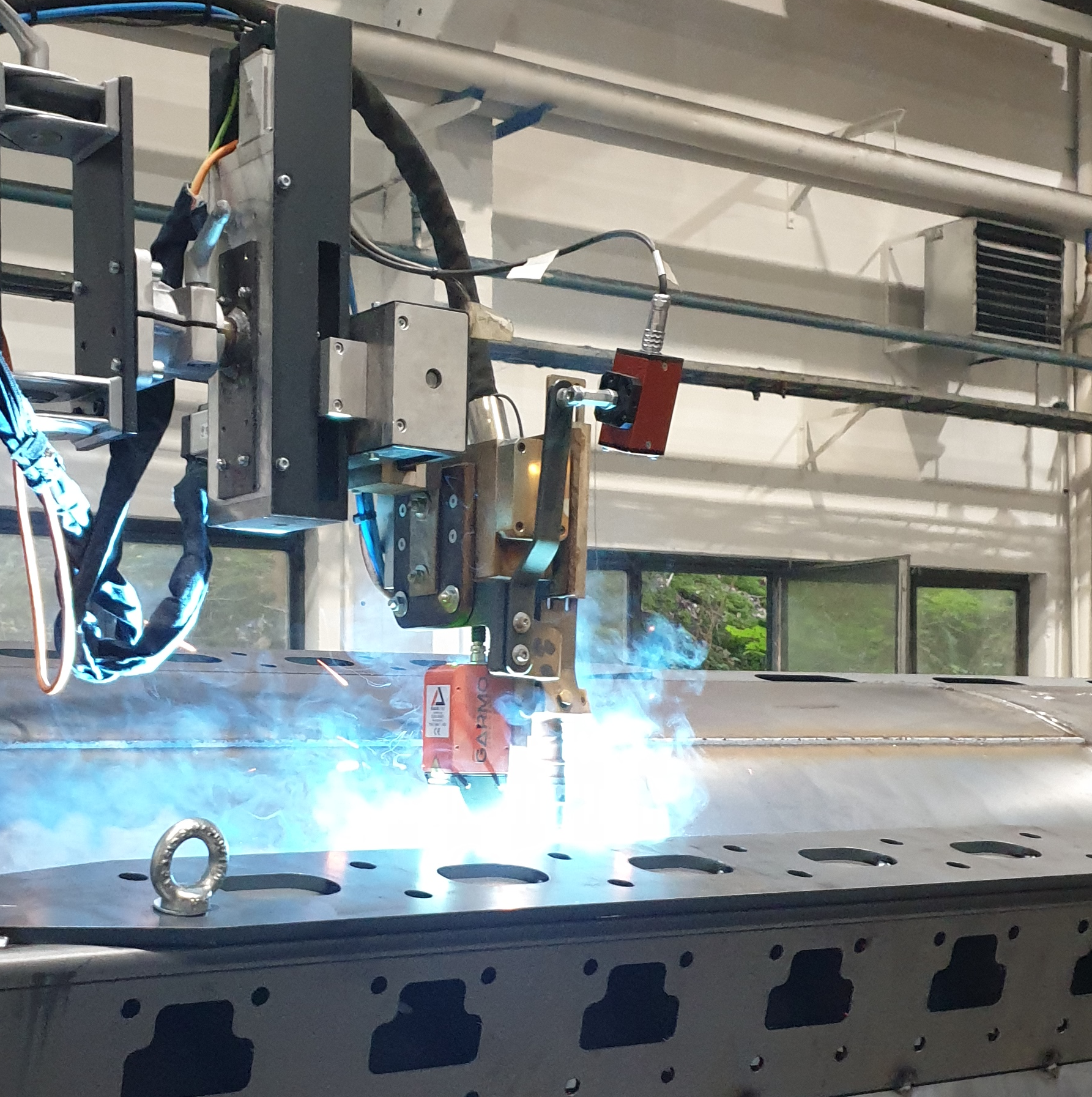

Laser tracking welding sensors play a key role in industrial automated welding, especially when integrated with programmable logic controllers (PLCs). Automated welding is now even easier, more accurate and more efficient thanks to the GarLine PLC laser seam tracking welding sensor.

Discover the unique sensor for multiple welding systems.

Smart and flexible welding

GarLine PLC sensor ensures better weld quality than the one obtained with traditional welding, and even with sensorless automated welding. During welding, GarLine PLC sends real-time corrections to the torch while making adjustments to welding parameters, such as arc speed and current, to maintain proper alignment.

Thanks to its robust design and advanced electronics, GarLine PLC sensor performs successfully in harsh environmental conditions, making your welding process more accurate, faster and safer.

Boundless welding options with PLC

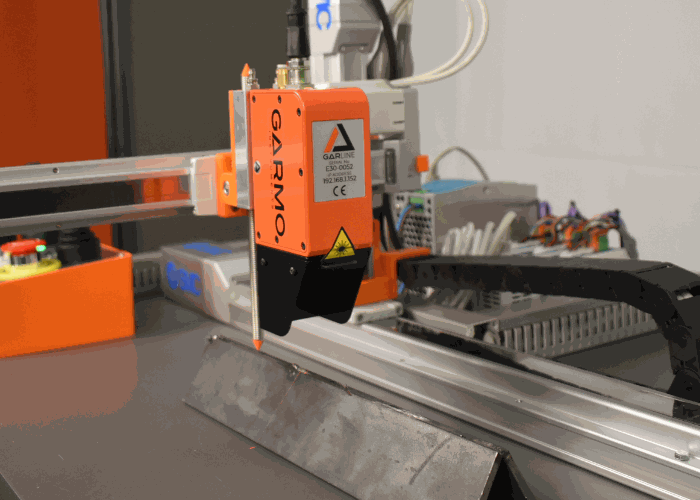

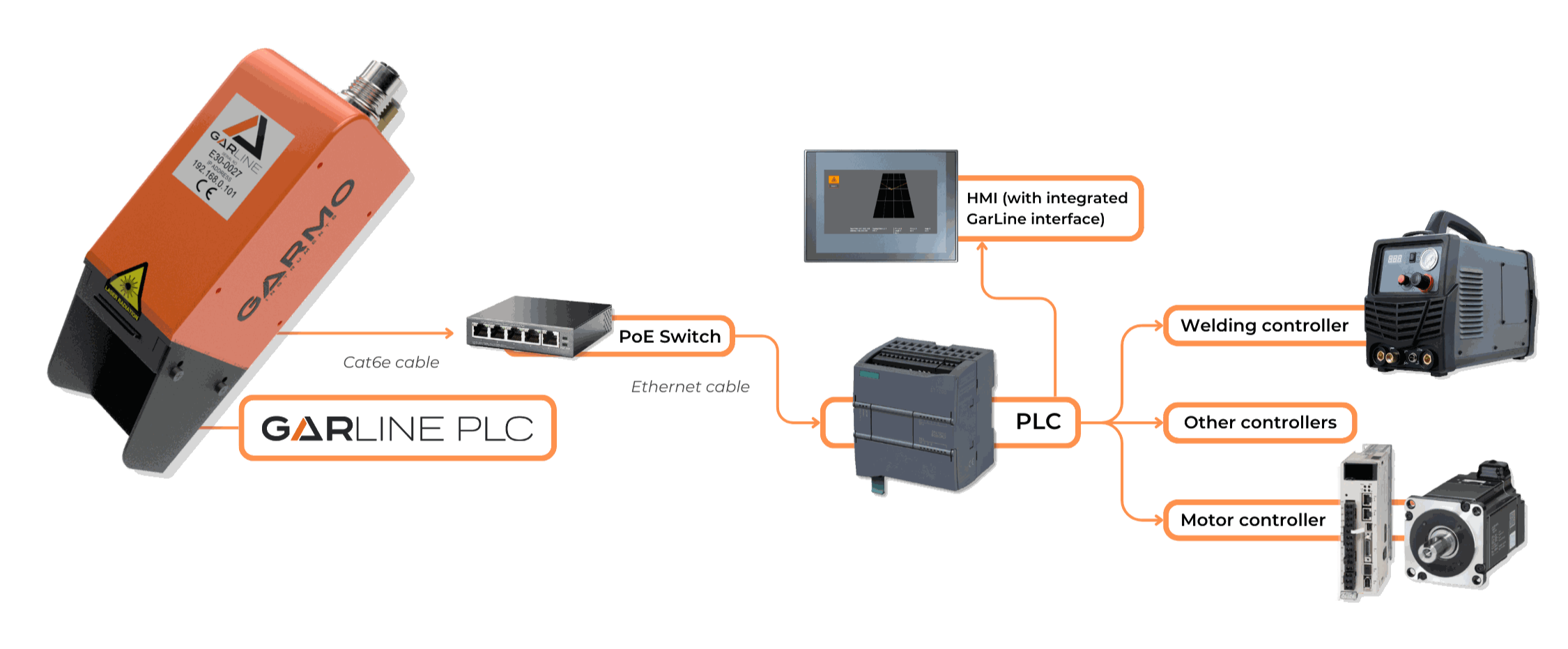

Thanks to the libraries installed in the sensor, seam type selection and seam customization, GarLine PLC can be easily integrated on different types of automated welding systems and diverse applications without any need for additional devices, and reducing installation costs.

Smart and adaptive welding

GarLine offers direct connection to PLC, featuring multiple configuration options and 3-axis correction.

End-detection tracking

The sensor detects the end of the seam and stops the welding at that point.

Seam

tracking

Real-time calculation of corrections to guide the welding torch path.

Adaptive welding

The sensor guides the torch to make straight or waving welding depending on gap width.

And much more! Discover more about GarLine PLC, its functions and application examples on our YouTube Channel!

Multiple libraries available

The sensor includes customizable welding setup, with multiple mode configurations available (e.g., fixing sensor to axes, turn axes on/off, welding speed, current, seam position, etc.).

Communication libraries easily adaptable to welding system’s interface code.

How can we help you?

Got a welding application and want to improve it? Get in touch with us, tell us about your welding application and our technical team will assist you with the solution that suits you the best!

Email: info@garmo-instruments.com