Wolrd's first laser seam tracking sensor for cobot welding, that fully combines cutting-edge technology, robust design and user-friendly interface. GarLine C features highest quality materials, unique functions and leading-edge technology. Plus, it’s the only sensor with own and UR-approved URCap.

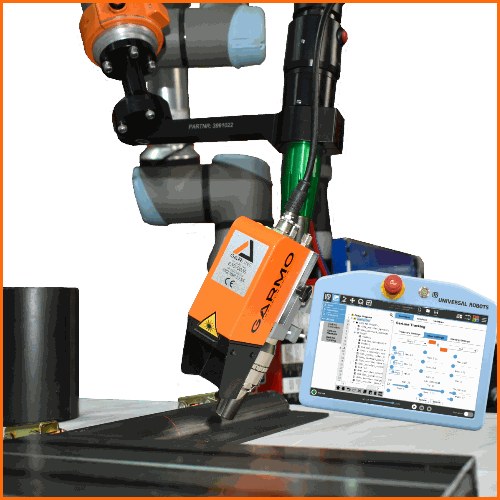

Cobot's best welding ally

A unique sensor, ideal for high-mix and low-volume applications. Garline C laser sensor allows cobots to handle complex seam geometries, including irregular shapes and variable angles.

Increased flexibility

Cobot welding combined with GarLine sensor allows total portability in the workshop, without a need for clamping and support elements to be related to the cobot. Forget about complex fixings, and just let GarLine and your UR cobot do all the work for you.

Integrated URCap

Introducing the only sensor with own and Universal Robots-approved URCap

Seam Search

The sensor finds the right teach points of the welding seam before the weld, to compensate the part deviation; finding also the start and the end point of the seam.

Seam tracking

The programming of complex shapes can be a consuming task. Thanks to GarLine you just need to mark the starting and ending points so the sensor detects the geometry of the complex seams to adapt the welding path, even on irregular shapes and variable angles.

Location

GarLine scans 4 points of the piece, placing it on the plane. Then, the sensor calculates the displacement and rotation offsets obtained with reference to the programmed part, applying these offsets to the original program.

And much more!

Find out more GarLine C benefits, functions and special URCap nodes on our YouTube Channel!

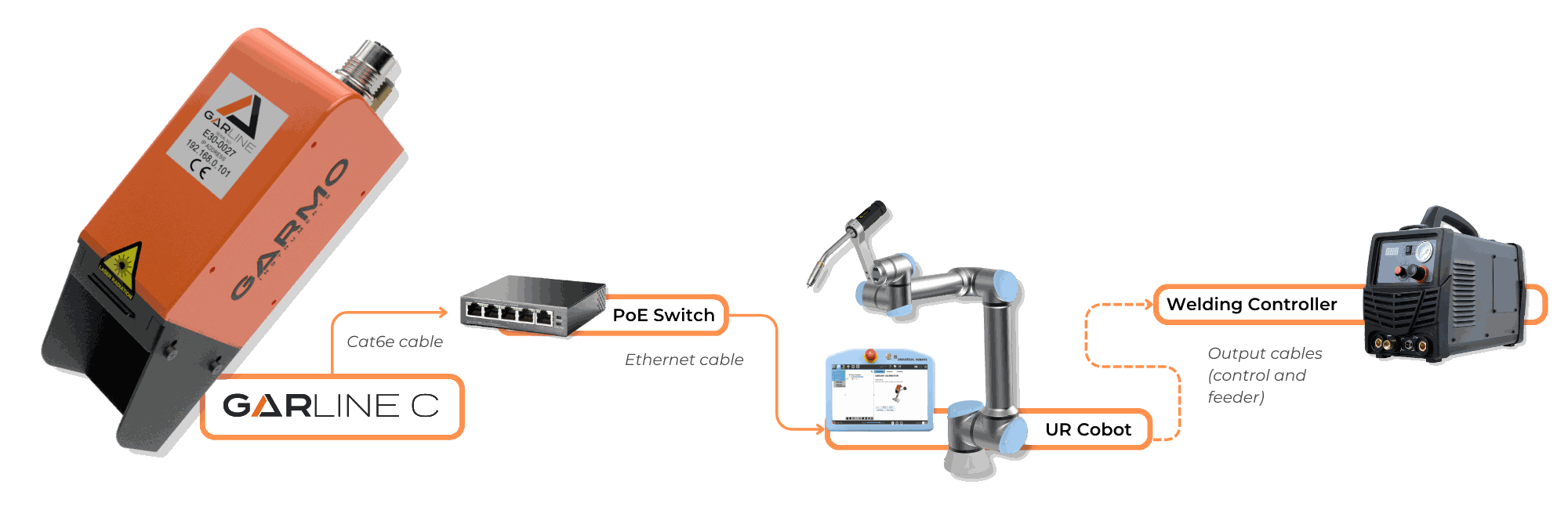

Easy setup

Thanks to their design, GarLine sensors feature the easiest cobot integration setup.

Vision programming® developed for your safety

Thanks to GarLine's Vision Programming function in cobot welding, workers are performing in a safer and healthier environment, avoiding direct exposure to welding fume and spatters.

Integrating GarLine into automated welding reduces the need for manual intervention, allowing operators to focus on monitoring the process rather than physically adjusting the torch.

The sensor calculates torch positioning during welding programming, which shortens process time and reduces operator training requirements for task performance.

Among seam tracking sensors, GarLine C is the only sensor with this patented® option

We work with

How can we help you?

Got a cobot welding application and need a seam tracker? Get in touch with us, tell us about your case and our technical team will assist you.

Email: info@garmo-instruments.com