Introducing GarLine R: The advanced laser solution for tracking weld seams for industrial robots.

Get the most out of robotic welding with GarLine R for industrial welding robots.

Smart and flexible welding

Thanks to its advanced electronics, GarLine R adjusts the robot path dynamically, compensating any deviation caused by material variations or small misalignments, making the welding process more accurate and efficient. The sensor operates successfully in harsh environmental conditions, including TIG welding, while providing real-time seam tracking.

Noticeable quality improvement

Welding with GarLine R and an industrial robot ensures a significantly better weld quality than the traditional welding process, avoiding the risk of defects such as undercuts, excess material and incomplete fusion.

Easy Integration

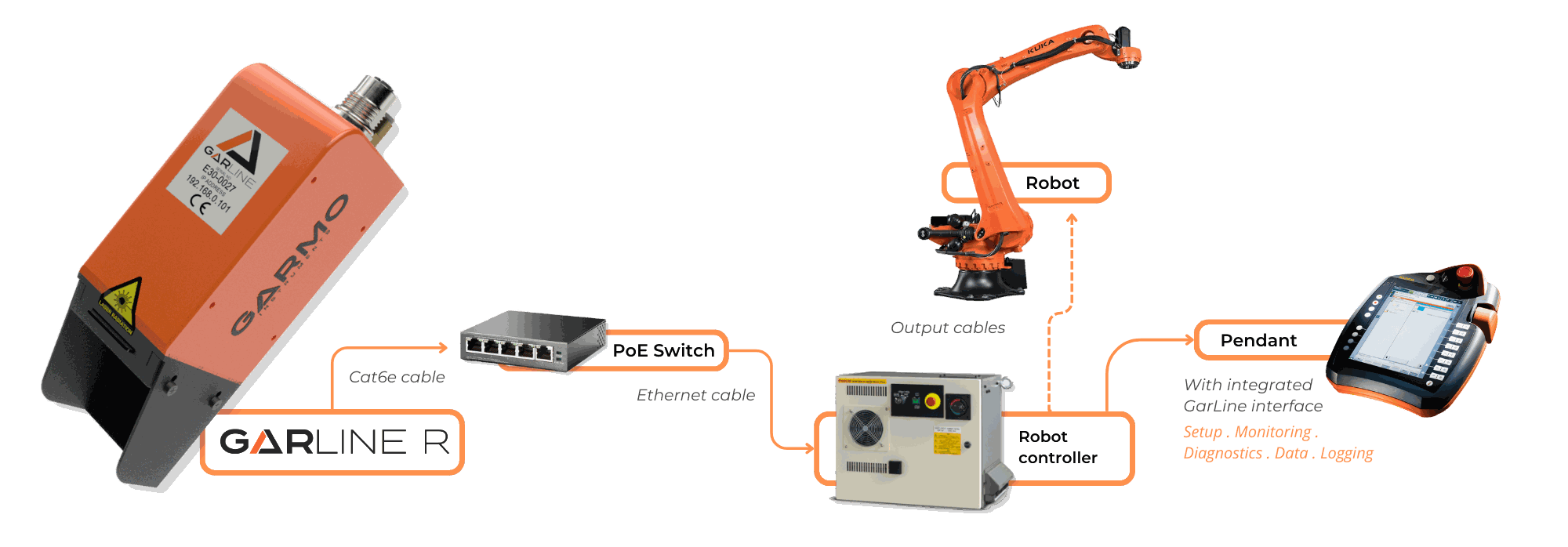

Controlling GarLine R sensor directly from robot's Pendant is now much easier. GarLine R integrated on the industrial robot will ease the welding process, thanks to some unique features.

Seam tracking

Real-time look-ahead seam tracking for an outstanding welding guidance. This function significantly reduces programming time.

Seam search

Sensor finds the seam start and end points and redirects the robot arm towards them.

Location

Sensor scans 4 weld positions and locates the welding trajectory 10 times faster than with only Touch Sense function (or similar). GarLine R measures rotation and translation in 3 axes each, calculating a total of 6 seam positions.

And much more! Find out more GarLine R benefits and functions on our YouTube Channel!

Plug&Play Setup

GarLine R sensors are designed ensuring an easy integration on industrial welding robots. For the first time, only one standard Cat6e cable and PoE switch are required for a complete integration, reducing installation costs.

How can we help you?

Got a robotic welding application? Get in touch with us, tell us about your case and our technical team will assist you with the solution that suits you the best!

Email: info@garmo-instruments.com